High purity alumina (HPA) is a pure form of aluminium oxide (Al2O3), with a minimum purity level of 99.9% or 3N. HPA is a high value and highly demanded product in specialty applications due to its chemical inertness, hardness, and electrical and thermal properties. Currently the global market for HPA is dominated by demand from synthetic sapphire producers, with synthetic sapphire wafers used in downstream production of LEDs, semiconductors, and scratchproof glass for watches and handheld electronic devices. A growing market for HPA is in the lithium-ion battery sector, and other rechargeable battery markets, where it is being used as an insulating coating material on polymer separators used within the battery for thermal protection.

HPA products are typically found in two forms in the market; a powder form used for coating applications in the phosphor lighting and lithium-ion battery sectors, where particle size distribution and surface area specifications are critical; and a pellet or bead product for use in synthetic sapphire boule production where the bulk density becomes a more critical physical parameter. Limits on individual elemental impurity concentrations such as sodium (Na), iron (Fe), and magnesium (Mg) are also typically specified, as these impurities can result in significant quality and safety issues in the end use applications.

High Purity Alumina (HPA)

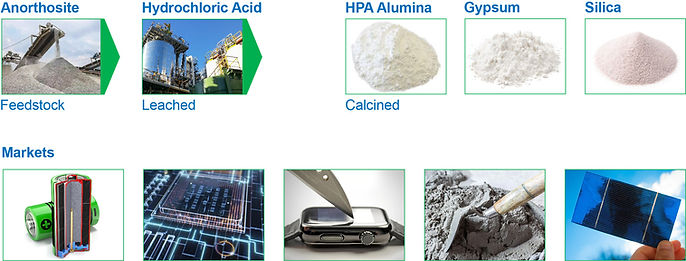

High purity alumina is a critical mineral required for the production of synthetic sapphire sapphire/LED industry and the rapidly expanding lithium-ion battery industry. Synthetic sapphire is used in the manufacture of LED lights, semiconductor wafers and scratch-resistant sapphire glass

High Purity Alumina (HPA)

Production Simplicity and Sustainability

Competing Process

The Bayer process is responsible for 90% of the world's alumina production. Two tons of red mud toxic waste remains after the production of one ton of aluminum. HPA production using the Bayer process is expensive, energy intensive and produces large quantities of toxic waste.

EnviroMine’s Process

EnviroMine’s process produces zero waste and the hydrochloric acid is recycled. HPA production using the EnviroMine process is less energy intensive and produces valuable bi-products for the production of a CO2 free cement.